Odour optimised, energy efficient, recyclable. And for specific applications: super clean and food contact compliant.

Recycled pellets of the future can do more. Get more out of your post consumer material flow with innovative EREMA technologies featuring digital assistance systems. More quality, more productivity. For a better end product.

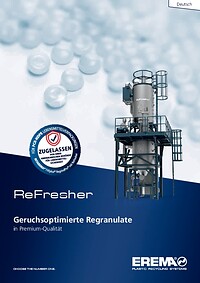

Take the new energy saving dual filtration solution INTAREMA® TVEplus® DuaFil® Compact, for example, as well as proven ReFresher anti odour technology and the smart predictive maintenance tool Predict:On. Enter this future right now with EREMA. Enter the new era of recycling.

Heavy contamination and mixed, damp material make recycling post-consumer plastics a complex challenge. To obtain high-quality secondary raw materials from them requires particularly reliable, stable processes and plant that is robustly constructed. Maximum performance with high-quality processing are the ideal – such as that offered by the recycling systems from EREMA that are designed for post-consumer waste.

Your practical benefits

Economical and technically better.

Recycled waste becomes a lucrative secondary raw material

EREMA

DOWNLOAD CENTRE

Application Post Consumer

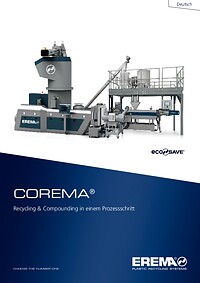

COREMA®

DD / Air Flush Module

EcoGentle

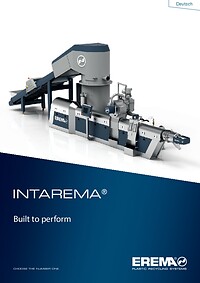

INTAREMA® image folder

INTAREMA® TVEplus®

INTAREMA® TVEplus® DuaFil® Compact

ReFresher

SW RTF®