INTAREMA® FibrePro:IV

PET fibre-to-fibre recycling

Spin finish under perfect control.

PET fibre-to-fibre recycling as a fine art.

Ready for respinning. The 100% rPET pellets produced by the INTAREMA® FibrePro:IV have it all: high colour fidelity and the excellent mechanical properties needed for further processing into ultra-fine, 100% recycled PET fibres with a titer of 2 dtex. Suitable for filament, staple and BCF fibres.

As a result of its efficient cleaning and recovery performance, the new INTAREMA® FibrePro:IV is also the first choice for especially challenging input materials such as PET fibres that are heavily contaminated with spin finish and have high levels of moisture.

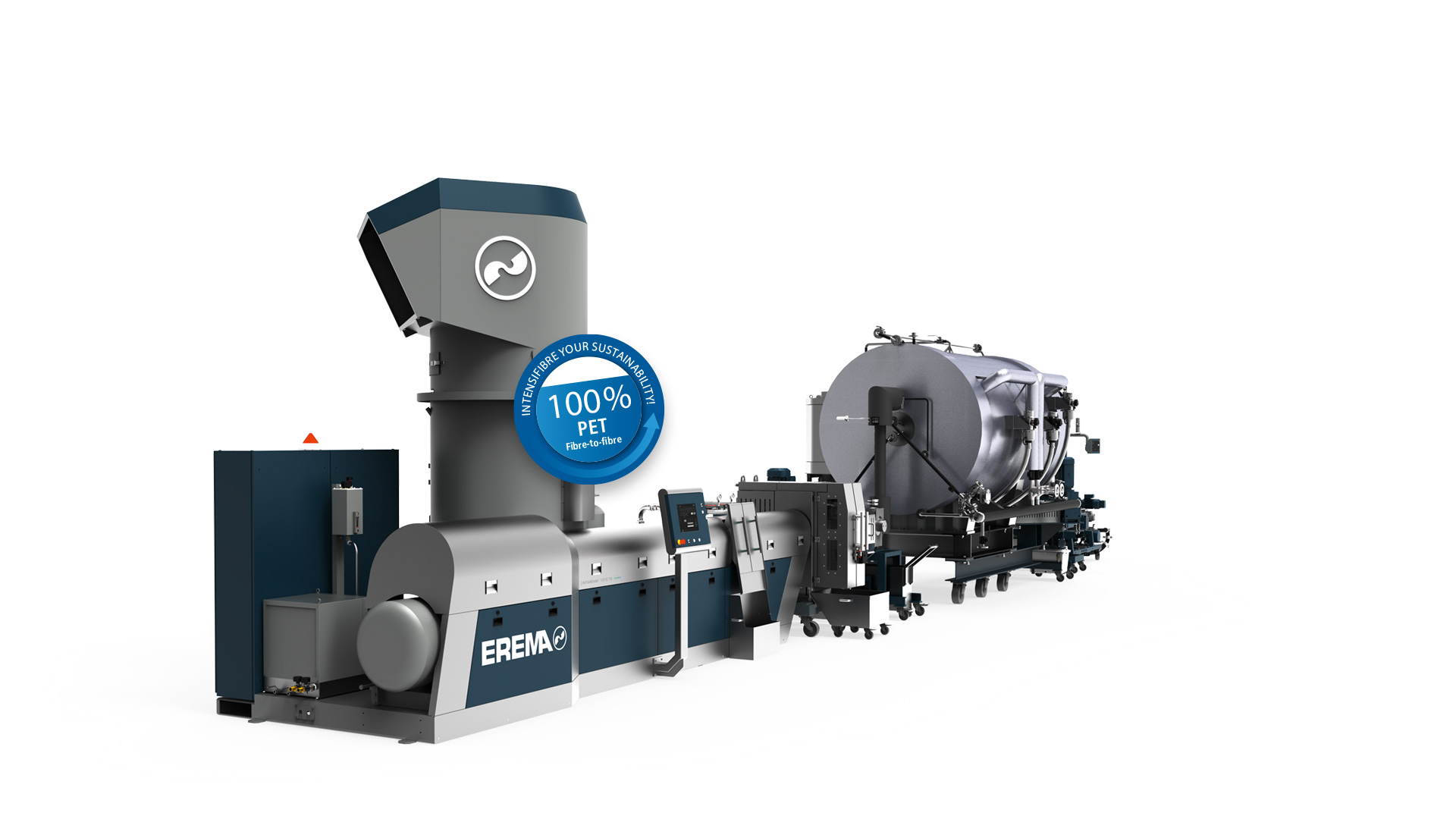

Unique combination of technologies: INTAREMA® & IV Uptimiser

This is made possible by combining the INTAREMA® machine, which has proven itself thousands of times over, with innovative IV Uptimiser technology. While the INTAREMA® prepares the material for extrusion using its Preconditioning Unit and Counter Current technology to ensure perfect homogenisation, pre-drying, removal of volatile components, and subsequent gentle PET melting, the new IV Uptimiser ensures repolymerisation, IV lift and efficiently cleans the fibres of finishing additives.

Future textile recycling in sight

EREMA is leading the way in PET fibre-to-fibre recycling with innovative solutions - an important contribution to today's circular economy. The company has set a significant milestone on route to future textile recycling.

Your benefits

Economical and technically better.

Intensifibre your sustainability!

PET fibre-to-fibre recycling

Spin finish under perfect control

How it works

INTAREMA® FibrePro:IV

Preconditioning Unit:

Ideal material preparation

Cutting, homogenising, heating, drying (input material with up to 10 % moisture), compacting, buffering and dosing – in a single process. The patented, dynamically controlled preconditioning unit gives the material the best possible preparation for the downstream tangentially connected extruder.

FIBRE RECYCLING CENTRE

in Austria

Test us - using your material

At our state-of-the-art Fibre Recycling Centre in Austria, you can use our selection of PET fibre recycling machines and technologies for trial runs with your own test materials. The tests are carried out in realistic production conditions and therefore provide the results you need to optimise your specific machine configuration – tuned precisely to your application.