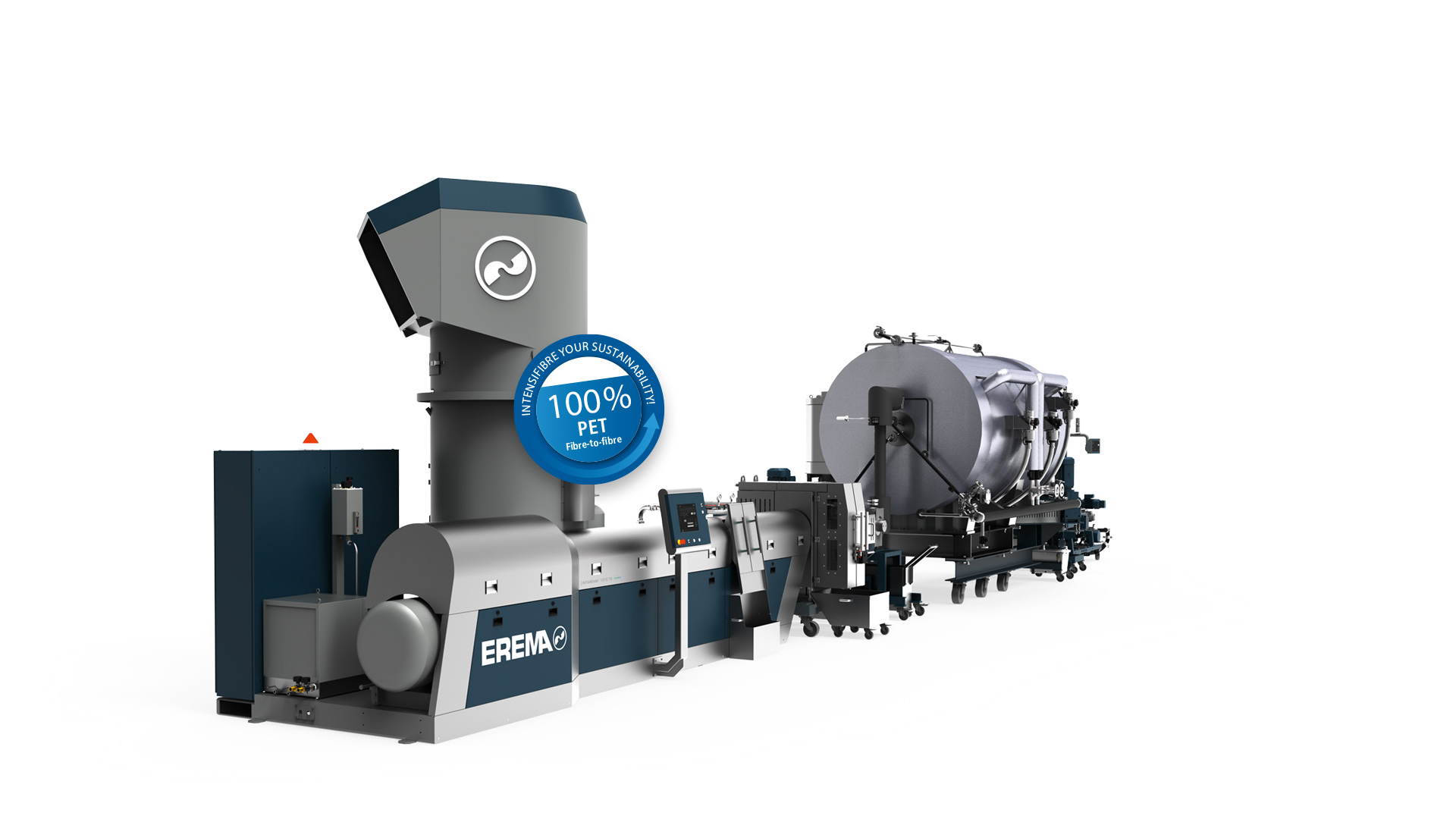

INTAREMA® FibrePro:IV

PET Faser-zu-Faser Recycling

Lower temperature, less energy.

For the finest double filtration quality in a compact design.

The innovative INTAREMA® TVEplus® DuaFil® Compact achieves the finest, double filtration recycled pellet quality in an extremely energy-saving way, and as a result sets the benchmark for production efficiency in post-consumer recycling.

Proven system, enhanced with even more efficiency

Highly flexible and at the same time extremely process-stable, the double filtration machine handles the melt particularly gently, and does so throughout the entire machine. This is the result of combining TVEplus® technology, patented and proven thousands of times over, with the new, patent-pending DuaFil® Compact design. Here, the melt pump takes over the necessary pressure build-up for the second filtration unit, so the extruder no longer needs to do this task and can be made signifi cantly shorter. In turn, this significantly reduces the residence time, the melt temperature and the energy consumption. And brings real advantages to the quality of melt and the recycled pellets

This makes the machine the first choice for many challenging materials. Especially when the application requires polymer-conserving processing as well as strong filtration performance in order to produce an end product with the best recycling quality

Zukunft Textil- recycling im Blick

EREMA treibt das Thema PET Faser-zu-Faser Recycling mit innovativen Lösungen führend voran – ein wichtiger Beitrag für die Kreislaufwirtschaft von heute. Und: Ein bedeutender Meilenstein für das Textilrecycling von morgen.

Your benefits

Economical and technically better.

Minus 10 L/D:

Much shorter and

more compact design

How it works

INTAREMA® TVEplus® DuaFil® Compact

Preconditioning Unit:

Ideale Materialvorbereitung

Schneiden, homogenisieren, erwärmen, trocknen (Eingangs- material mit bis zu 10 % Feuchtigkeit), verdichten, puffern und dosieren – in einem Arbeitsschritt. Die patentierte, dynamisch kontrollierte Preconditioning Unit bereitet das Material bestmöglich für den direkt tangential angeschlossenen Extruder auf.

FIBRE RECYCLING CENTRE

in Österreich

Testen Sie uns – mit Ihrem Material

In unserem hochmodernen Fibre Recycling Centre in Österreich können Sie unsere unterschiedlichen PET-Faser-Recycling- Maschinen und Technologien für Probeläufe mit eigenen Testmaterialien nutzen. Die Tests finden unter realistischen Produktionsbedingungen statt und liefern daher jene Ergebnisse, mit denen anschließend Ihre Maschinenaus- legung individuell optimiert wird – exakt und punktgenau abgestimmt auf Ihren konkreten Anwendungsfall.