Our innovative recycling solutions are an essential part of our customers' success stories around the world. Learn more here:

Strong partnership drives plastics recycling in China

Jiangsu Ceville New Materials Technology Co, Ltd, a leading Chinese recycling company, signed the purchase of another VACUREMA® plant in June 2024.

Since K 2022, EREMA has sold around 20 INTAREMA® TVEplus® DuaFil® Compact systems. The first machines have been delivered and have now entered operation. At RECUPAC S.A., for example, a recycling and waste disposal company based in Chile.

November 16, 2023, saw the official celebration for the opening of ALOXE's new production plant in Messein (France). Here, they recycle post-consumer PET bottles and process them into high-quality pellets. EREMA is the technology partner and supplied two

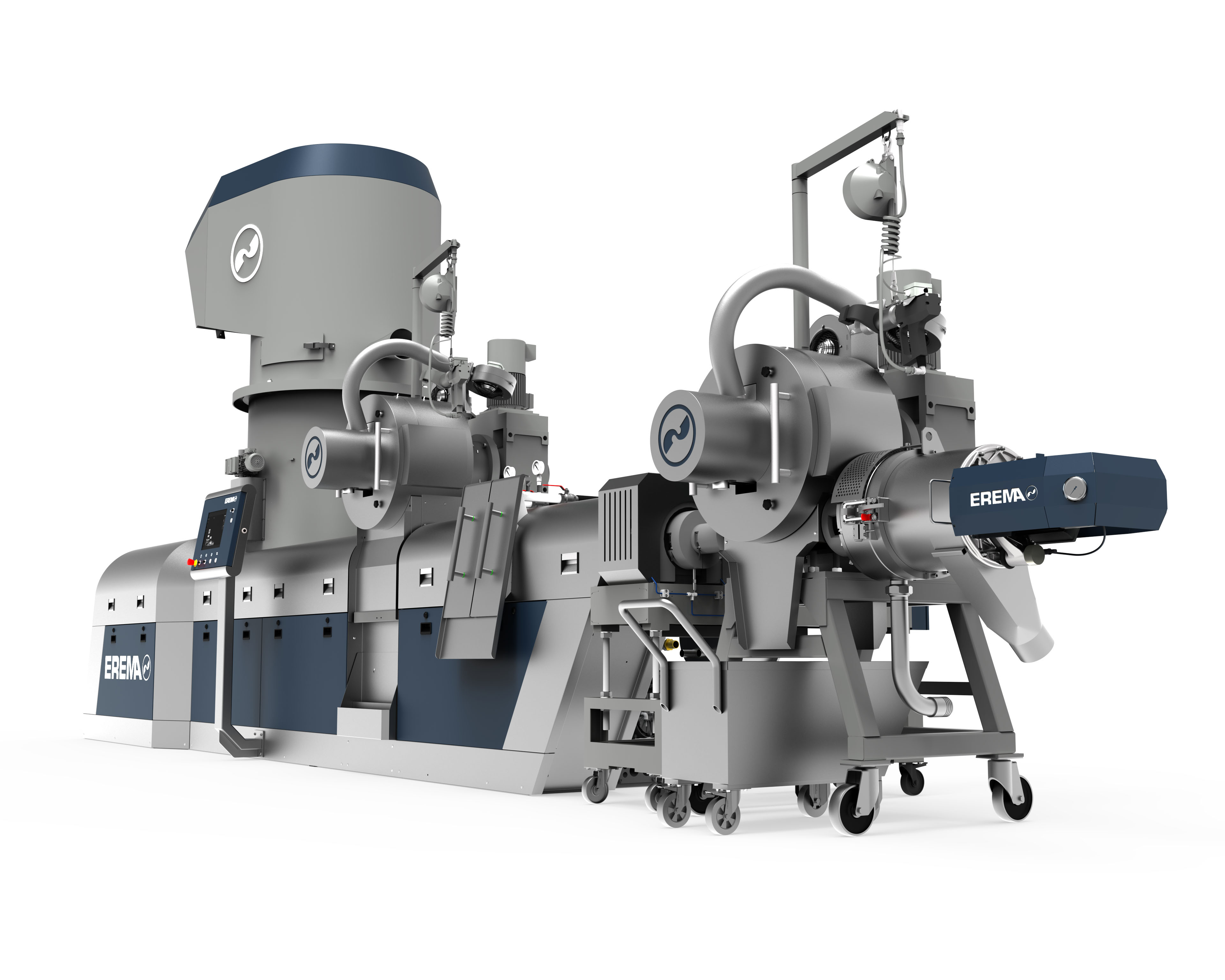

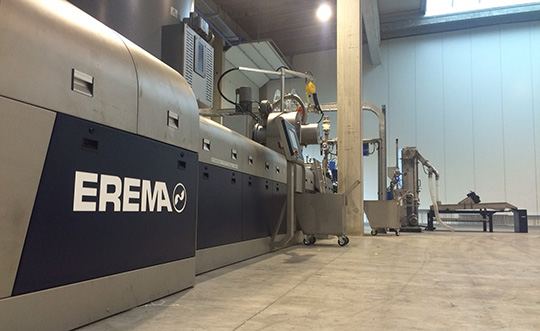

EREMA’s CHEMAREMA® extrusion-based raw material preparation – maximum feedstock flexibility and highly energy-efficient in one single process step

EREMA’s CHEMAREMA® extrusion-based raw material preparation – maximum feedstock flexibility and highly energy-efficient in one single process step

Large packaging and pipe manufacturer in the southern Balkans uses their own recycled granulate made with EREMA’s latest recycling system

Weltplast produces packaging and pipes from recycled and biodegradable materials. They are a state-of-the-art manufacturer that engages fully in the circular economy.

Industry leader, Clean R, recycles plastics with EREMA’s INTAREMA® TVEplus® recycling system

Clean R recycles an average of 50,000 tonnes of plastics and packaging a year, preventing it from going to a landfill. Recycled waste becomes a lucrative secondary raw material for the production of a variety of products.

Serbian company recycles film from collected from household waste to produce new film for the construction industry

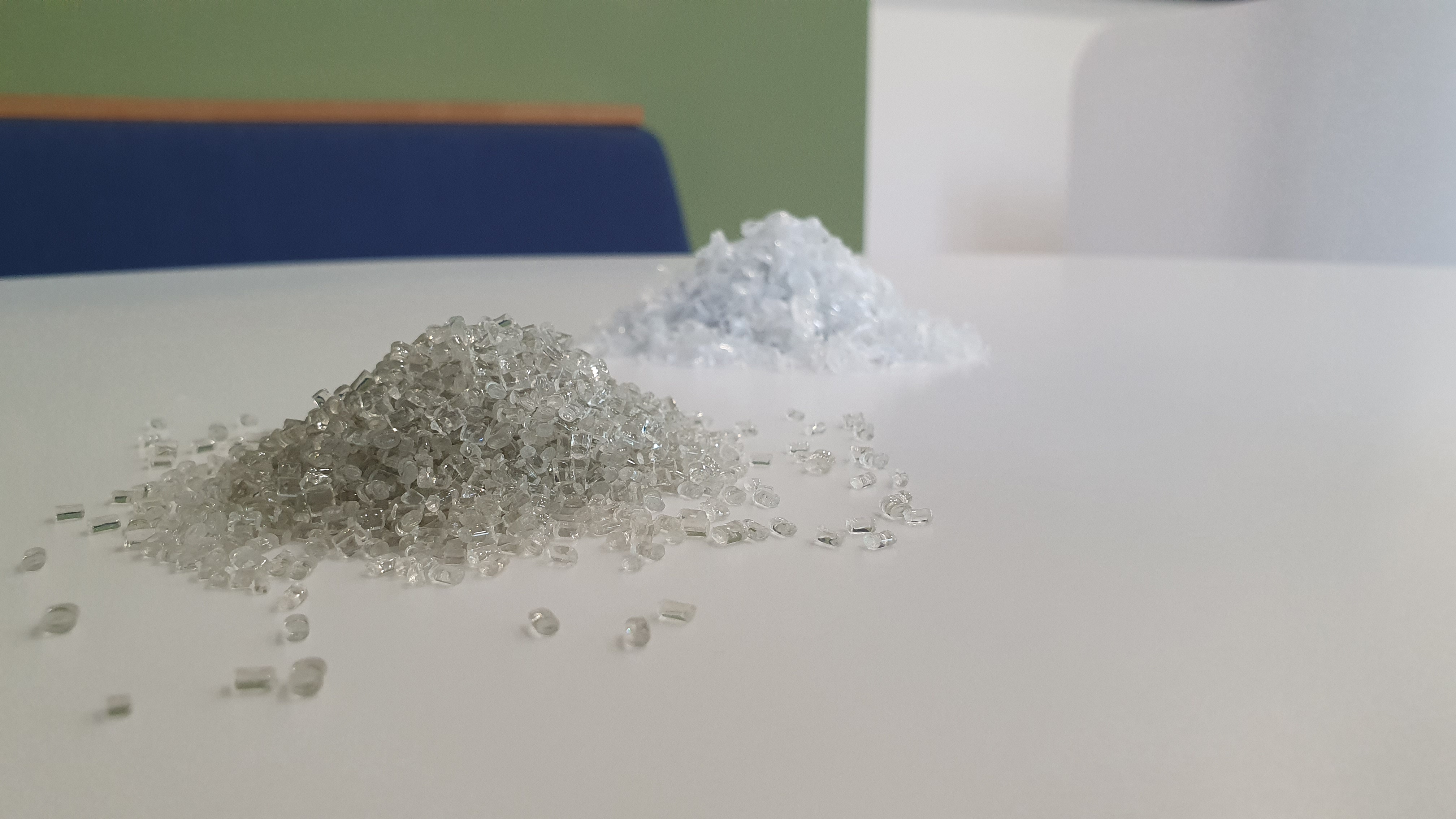

"The quality is simply perfect!". That is how Dejan Simic, owner of the Serbian plastic waste processor Brzn Plast d.o.o., assesses the recycled pellets produced by his company since July 2022 using the new INTAREMA® TVEplus® technology from EREMA.

Recycling technology with double filtrations for clean tech startup Healix

A closed-loop solution for plastic fibre waste from fishing, shipping and agriculture - this is the challenge accepted by Healix, a cleantech startup founded in Maastricht (NL) in 2021.

German recycling company produces food contact compliant rPET using EREMA's new VACUNITE® bottle-to-bottle system

One of the first VACUNITE® bottle-to-bottle systems recently started operation in Werne/Germany. Using this system, the RCS Group, who already produce PET flakes for the non-food sector...

Pioneering plastics recycling company continues to rely on EREMA technology in the future

In Austria, the beginning of plastics recycling is inseparably linked with the name Osterberger Kunststoff Verwertung (OKUV) Blaimschein.

INTEGRA PLASTICS combines all the process steps in one recycling plant

One of the world's most modern recycling plants went into operation in Sofia, Bulgaria, in May 2019. Its operator, Integra Plastics, uses this plant to specialise in the recycling of heavily contaminated post consumer household waste...

COREMA with re360 used successfully at INTERSEROH

Using the cascade extrusion system COREMA, the environmental service provider Interseroh produces tailor-made recompounds for very high-quality applications in just one process step.

TIVACO, Belgium

The Belgian company TIVACO recycles post-industrial scraps in polypropylene, polyethylene, polystyrene and flexible PVC to make recycled pellets for the production of high-end products such as visible automotive parts or household articles ...

Buenos Aires, Argentina

The Argentinian company RECICLAR is continuing its success story as a South American pioneer in 2017, too. Following the successfully established business fields of PET flakes and PET recyclates ...

Arpema Plásticos, Mexico

While the demand for recycled pellets is increasing continuously, it is becoming more and more difficult to obtain clean post-industrial plastic waste...

Buergofol sees benefits in the use of recycled PET

"Transparent PET packaging has been a popular discussion topic with regard to food packaging for years," says Gregor Schleicher. "Even though APET films for this application have been commodity products for a long time...

Ambigroup Reciclagem

Ambigroup Reciclagem S.A. is a well-known and respected recycler of agricultural film, used agricultural irrigation tubing and other post-consumer waste in Portugal. The input materials are very moist and contaminated ...

EREMA and DORNIER combine machine components to create an innovative recycling solution

When two mechanical engineering technology leaders work together in order to fulfil specific customer requirements, unique recycling solutions are the result.

COPO PLAST, Germany

The first INTAREMA® system in Germany was installed in spring 2014 at Heinrich e.K. of Traunreut. Copo Plast uses its TVEplus® 1310 with Laserfilter LF 2/350 to process 10,000 tonnes of heavily printed multilayer materials ...

World's first FTP plant impresses recyclers and beverage bottlers

Kyoei Industry - the Japanese plastics recycling company - put into operation in the summer of 2018 the world's first plant that directly produces new PET bottle preforms from 100 percent recycled PET flakes.

RODEPA PLASTICS, Netherlands

Rodepa processes 25,000 tonnes of post-industrial and post-consumer LDPE, PP and PS every year to make recycled pellets. RegrindPro® has proven to be particularly efficient in the processing of thick-walled regrind ...

OKUV BLAIMSCHEIN GMBH, Austria

Family-run OKUV Blaimschein GmbH located in St. Marien near Linz, Austria, is a very successful recycling company based on toll recycling services. Owner Karl Blaimschein has placed his trust in EREMA for over 25 years ...

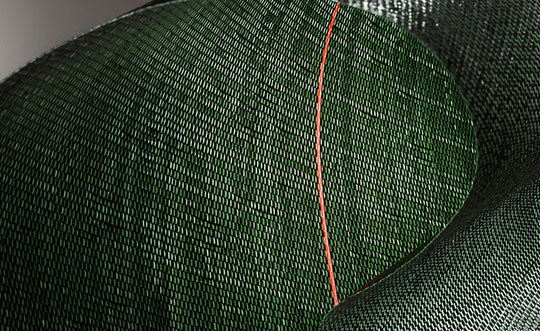

BEAULIEU TECHNICAL TEXTILES, Belgium

Beaulieu Technical Textiles (BTT), member of the Beaulieu International Group, is an established leader and driving force in the production of technical textiles made of PP, PE and biopolymers. Thanks to COREMA® Technology ...

WINGSPAN PLASTICS, South Africa

Wingspan Plastics, who have been successful in the market for ten years now and are the Western Cape’s second largest recycler of plastics, process 7,200 tonnes of post-consumer and post-industrial scrap a year to make recycled pellets ...

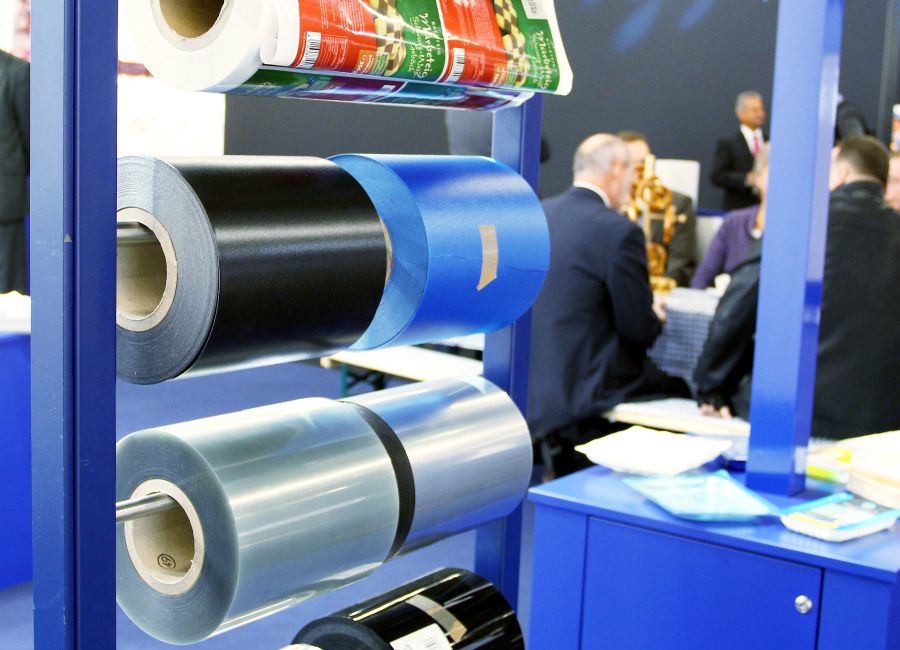

POLIFILM, Germany

Business with bin liners, construction and agricultural films in the highly competitive environment is only effective and worthwhile if recycling materials are used for their production – up to 100% in some cases. The use of recyclate, however, is also

Wang on Fibres Ltd, South Africa

South African company Wang on Fibres specializes in the manufacturing of durable PP packaging and woven plastic bags. An INTAREMA 1007 TVEplus is used to process clean and lightly printed in-house waste.

Recycling of HDPE milk bottles

London-based recycling company Closed Loop Recycling (now Veolia UK) began producing food-contact approved rHDPE from milk bottle material in 2008...

FVH Folienveredelung Hamburg GmbH & Co KG, Germany

FVH Folienveredelung Hamburg GmbH & Co. KG uses heavily contaminated film scraps as a raw material source at its production facility in Schwerin to make high-quality polyethylene plastic pellets ...