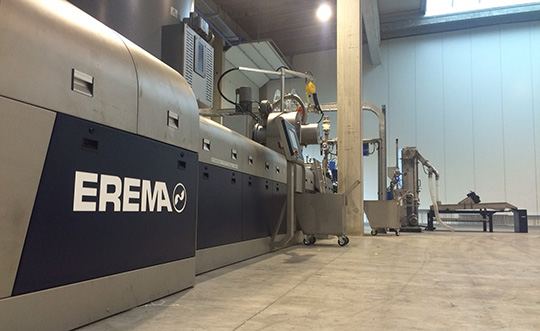

The versatile and creative injection moulding experts, MCL Components Ltd of Malta, use EREMA technology to process post-industrial plastic waste and make high-quality recycled pellets, which can be returned (up to 100%) to the production process.

MCL Components Ltd use an EREMA 756 TE pelletising system to make recycled pellets from not only injection moulding runners and regrind, but also from bottle caps, pallets, crates, containers, plastic bags, stretch wrap and rejected parts. The input materials to be processed range from ABS, TPE, EVA, POM, PELD, SAN, GPPS and HIPS to HDPE. The recycled pellets produced are then returned to the production processes of injection moulders in Malta and other countries, with the target being 100% reuse of the material. They are used, for example, by large multinationals operating in the fields of toy manufacture, automotive production parts, food and non-food packaging, to name only a few.

Consistent quality, enormous flexibility

The aim of MCL Components Ltd when investing in the system was clearly defined: to achieve recycled pellets with consistent quality, while processing a wide range of materials. This is why the company decided in favour of the world-leading plastics recycling technology from EREMA. According to the MCL team, the TE system more than fulfils this requirement: “The quality of the output is very good. Above all, the recycled pellets have only a minimum amount or no residual moisture, thereby enabling us to push towards our target of 100% reuse in the production process.”

| Application: | Inhouse & industrial recycling |

|---|---|

| Materials: | Regrind material (PE, PP, ABS, PS etc.) |

| Product category: | INTAREMA |

| Modell Details: | EREMA 756 TE |

POLIFILM, Germany

Business with bin liners, construction and agricultural films in the highly competitive environment is only effective and worthwhile if recycling materials are used for their production – up to 100% in some cases. The use of recyclate, however, is also

TIVACO, Belgium

The Belgian company TIVACO recycles post-industrial scraps in polypropylene, polyethylene, polystyrene and flexible PVC to make recycled pellets for the production of high-end products such as visible automotive parts or household articles ...