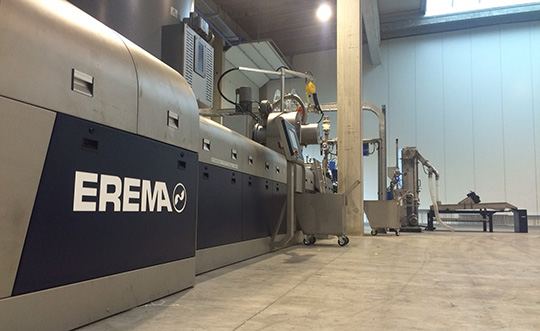

Since K 2022, EREMA has sold around 20 INTAREMA® TVEplus® DuaFil® Compact systems. The first machines have been delivered and have now entered operation. At RECUPAC S.A., for example, a recycling and waste disposal company based in Chile.

"As the business unit for waste management at Coipsa, a group of packaging companies in Chile that are fully integrated in all phases of the circular economy, we process more than 150,000 tons of different materials every year," says Philippe Morizon, General Manager at RECUPAC. Plastics recycling is a relatively new field for the company. For their first machine, they decided on an INTAREMA® 1512 TVEplus® DuaFil® Compact. The objective is to produce high-quality recycled pellets suitable for making film. "Our customers have very high quality specifications, which is why we chose an EREMA machine," emphasizes Morizon. "With this compact recycling machine, we can produce high-quality pellets that are used to make film and can be used for other applications in the packaging sector. There were many arguments in favour of this machine, including its high overall efficiency. Particularly important factors were its low energy consumption and high degree of automation, which saves on operating personnel. I am confident we will meet our customers' expectations, and the initial results are very promising."

Lindner washing system

RECUPAC also operates a Lindner washing system. In August last year, EREMA Group joined forces with the waste management specialist and founded a new holding company. The two companies want to work together to increase the energy efficiency of the overall process and further improve recyclate quality through technical cooperation.

| Application: | Post-consumer recycling |

|---|---|

| Materials: | PE film with paper labels, pallet wrap |

| Product category: | INTAREMA |

| Modell Details: | INTAREMA® 1512 TVEplus® DuaFil® Compact |

With the INTAREMA® 1512 TVEplus® DuaFil® Compact we can produce high-quality pellets that are used to make film and can be used for other applications in the packaging sector. There were many arguments in favour of this compact machine, including its high overall efficiency and its low energy consumption.

Philippe Morizon

General Manager bei RECUPAC, Chile

TIVACO, Belgium

The Belgian company TIVACO recycles post-industrial scraps in polypropylene, polyethylene, polystyrene and flexible PVC to make recycled pellets for the production of high-end products such as visible automotive parts or household articles ...