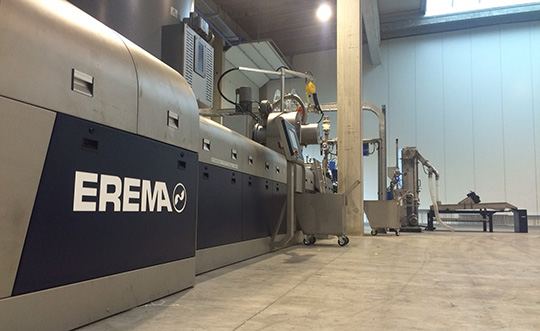

Wingspan Plastics, who have been successful in the market for ten years now and are the Western Cape’s second largest recycler of plastics, process 7,200 tonnes of post-consumer and post-industrial scrap a year to make recycled pellets for the film and injection moulding industry and are fully committed to EREMA technologies in doing so. The company appreciates above all the stable performance of its new INTAREMA® system.

The post-consumer input material mainly consists of PE films and HDPE regrind material from cosmetic bottles, screw tops and poison cans used in farming activities. The company also processes clean, sorted scrap plastic such as e.g. LDPE films with paper labels from pallet packaging from the post-industrial sector. Wingspan collects all these different plastics, sorts them, cleans them thoroughly in the washing lines which are specially configured for the respective material streams and then processes them to make high-quality black (from post-consumer scrap), smokey (from clean-sorted material) and clear (from very clean industrial scrap) recycled PE pellets.

Best recycling technology

When it comes to recycling technology, Wingspan has relied on EREMA for years and now has three successful systems in operation: an EREMA RGA, an EREMA 1310 TVEplus® and since 2014 the latest INTAREMA® 1310 TVEplus® with a capacity of approx. 600-700 kg/h. Johan van der Merwe, Wingspan General Manager, explains the main reason for his complete satisfaction as follows: “EREMA produces the most efficient, most reliable and most productive systems on the market. The new INTAREMA® is also extremely stable in production – even better than the previous systems.”

Plastics recycling as part of modern life

Johan van der Merwe explains: “Discarded milk or fabric softener bottles, ice cream tubs, plastic bags and even cling wrap can all be recycled and converted into something useful like a garbage bag, a comb, a rope, a car bumper, or even a kid’s toy. Recycling is becoming an important part of modern-day life and we are excited about playing a pivotal role together with EREMA in a greener future.”

| Application: | Post-consumer recycling |

|---|---|

| Materials: | PE film with paper labels, pallet wrap PE washed film flakes (e.g. DSD310) Regrind material (PE, PP, ABS, PS etc.) |

| Product category: | INTAREMA |

| Modell Details: | INTAREMA® 1310 TVEplus® |

Wang on Fibres Ltd, South Africa

South African company Wang on Fibres specializes in the manufacturing of durable PP packaging and woven plastic bags. An INTAREMA 1007 TVEplus is used to process clean and lightly printed in-house waste.

TIVACO, Belgium

The Belgian company TIVACO recycles post-industrial scraps in polypropylene, polyethylene, polystyrene and flexible PVC to make recycled pellets for the production of high-end products such as visible automotive parts or household articles ...