As part of the Kapersul Group, which works in the fields of industrial waste management and paper distribution, Plaskaper Termoplásticos S/A is the plastics recycling company of the group. Plaskaper produces around 12,000 tonnes of recycled pellets from LDPE, HDPE and PP every year at its facility in Brazil‘s Fazenda Rio Grande for film manufacturers in Brazil. Three high-capacity EREMA systems are used for this purpose and since the end of 2014 productivity has soared once again through the addition of a brand new INTAREMA® TVEplus®.

Plaskaper processes mainly post-consumer scrap LDPE amounting to 9,600 tonnes every year. The company also processes 1,200 tonnes of LDPE and the same amount of PP from post-industrial waste. Lauro Furuta, Plaskaper President, explains what the key issue is in the main application: “The main challenge is to have efficient cleaning and decontamination of the washed LDPE films, and the four EREMA systems we now have at our disposal offer the best recycling solution for this. We do have upstream washing plants but they have their ups and downs which mean residual moisture and residual contaminants at times. The preconditioning unit and Laserfilter in particular are successful in combatting these factors.”

3 EREMAS + 1 INTAREMA®

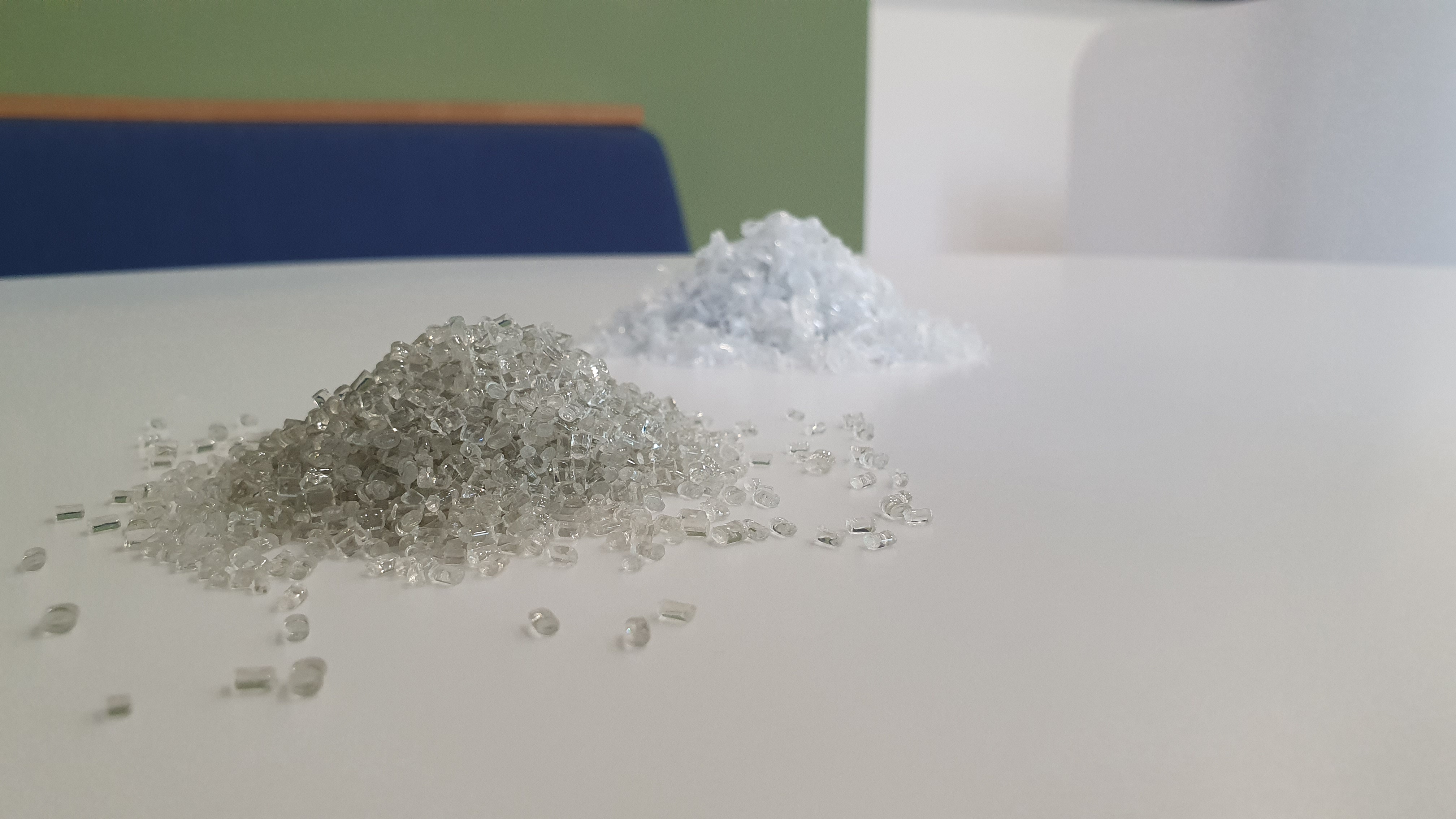

All in all Plaskaper has four EREMA systems in operation: an EREMA T, two EREMA TVEplus® systems and a new INTAREMA® 1716 TVEplus® with double Laserfilter 2/350-TWIN joined them at the end of 2014. “Unlike other extruder systems, Erema recycling technologies come with the special benefit that they are able to process washed flakes with much higher moisture levels with no trouble at all. Thanks to the new INTAREMA® we can even handle material with 8 to 10% residual moisture and peaks of up to 15% from time to time,” says a delighted Lauro Furuta, talking about the new system. The company is also enthusiastic about the fact that energy consumption is even lower although output is higher than with the previous EREMA systems. Process stability, above all through the PLC, is a further key benefit for Plaskaper. The values for filtration and degassing are likewise very stable and the system produces in general more homogeneous material of even higher quality. Lauro Furuta considers this process stability to be extremely important, especially for the future: “The amount of co-extruded material with several layers and additives that you cannot separate is growing continuously. PE, PET, EVOH and PA often pose major challenges.”

Growing market

The company ranks among the leading LDPE post-consumer recyclers in Brazil, where the recycling market is still small but growing steadily and has high growth potential. Plaskasper sells the recycled LDPE pellets to plastics processors who use them to make blown film for e.g. shopping bags and agricultural and construction use. The recycled PP pellets are used for injection moulding applications.

| Application: | Inhouse & industrial recycling Post-consumer recycling |

|---|---|

| Materials: | |

| Product category: | INTAREMA |

| Modell Details: | INTARMEA® 1716 TVEplus® mit Doppellaserfilter 2/350-TWIN |

Lauro Furuta

President of Plaskaper

EREMA and DORNIER combine machine components to create an innovative recycling solution

When two mechanical engineering technology leaders work together in order to fulfil specific customer requirements, unique recycling solutions are the result.

Arpema Plásticos, Mexico

While the demand for recycled pellets is increasing continuously, it is becoming more and more difficult to obtain clean post-industrial plastic waste...