For more quality and higher process stability.

Continuous quality monitoring of colour and MVR values directly at the recycling machine.

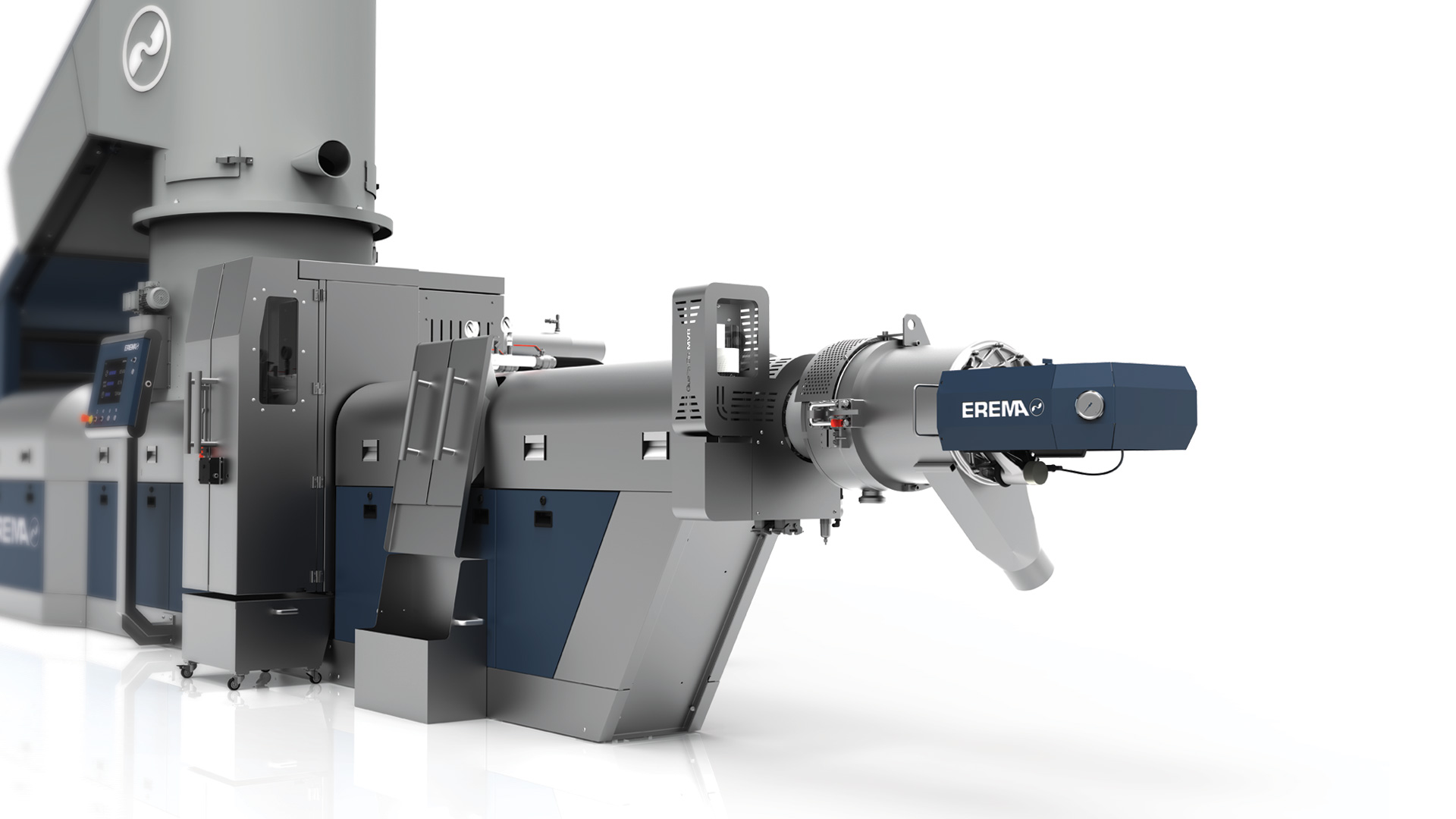

QualityOn redefines the standard for monitoring quality in plastics recycling. Because thanks to the innovative EREMA online measuring features you are informed about the current MVR and colour values already while the machine is processing – and do not have to wait until later in the laboratory.

As soon as the values measured leave the defined tolerance range you automatically receive an alert and can take prompt remedial measures in the process or flush flawed material from the process while it is still running.

This ensures that you and your customers have recycled pellets with consistent properties. For more quality and higher process stability. Another bonus: QualityOn saves a great deal of time and work compared to conventional laboratory methods.

Your benefits.

Economical and technically better.

Continuous quality monitoring of colour and MVR (melt volume-flow rate) values at the machine during processing – no need to wait until later in the laboratory

QualityOn & RE360

A strong team

Get more out of your QualityOn data – with re360, the new EREMA manufacturing execution system (optional).

This system gives you a clear view of the MVR and colour data, prepares them in a structured way for later data analysis and enables the necessary long-term data storage for quality documentation.

QualityOn:Polyscan

Precise online measurement of the polymer and filler composition of the input material in real-time directly at the Preconditioning Unit (PCU)

Your benefits.

Economical and technically better.

QualityOn:Colour

Precise online measuring of pellet colour in real time directly at the machine

Your benefits.

Economical and technically better.

QualityOn:MVR

Continuous online measuring of melt volume-flow rate (MVR) in real time directly at the machine.

Your benefits.

Economical and technically better.

QualityOn:IV

Continuous online measuring of intrinsic viscosity (IV) in real time directly at the machine. The measured value is already the final IV value which the finished pellets will also have.

Your benefits.

Economical and technically better.