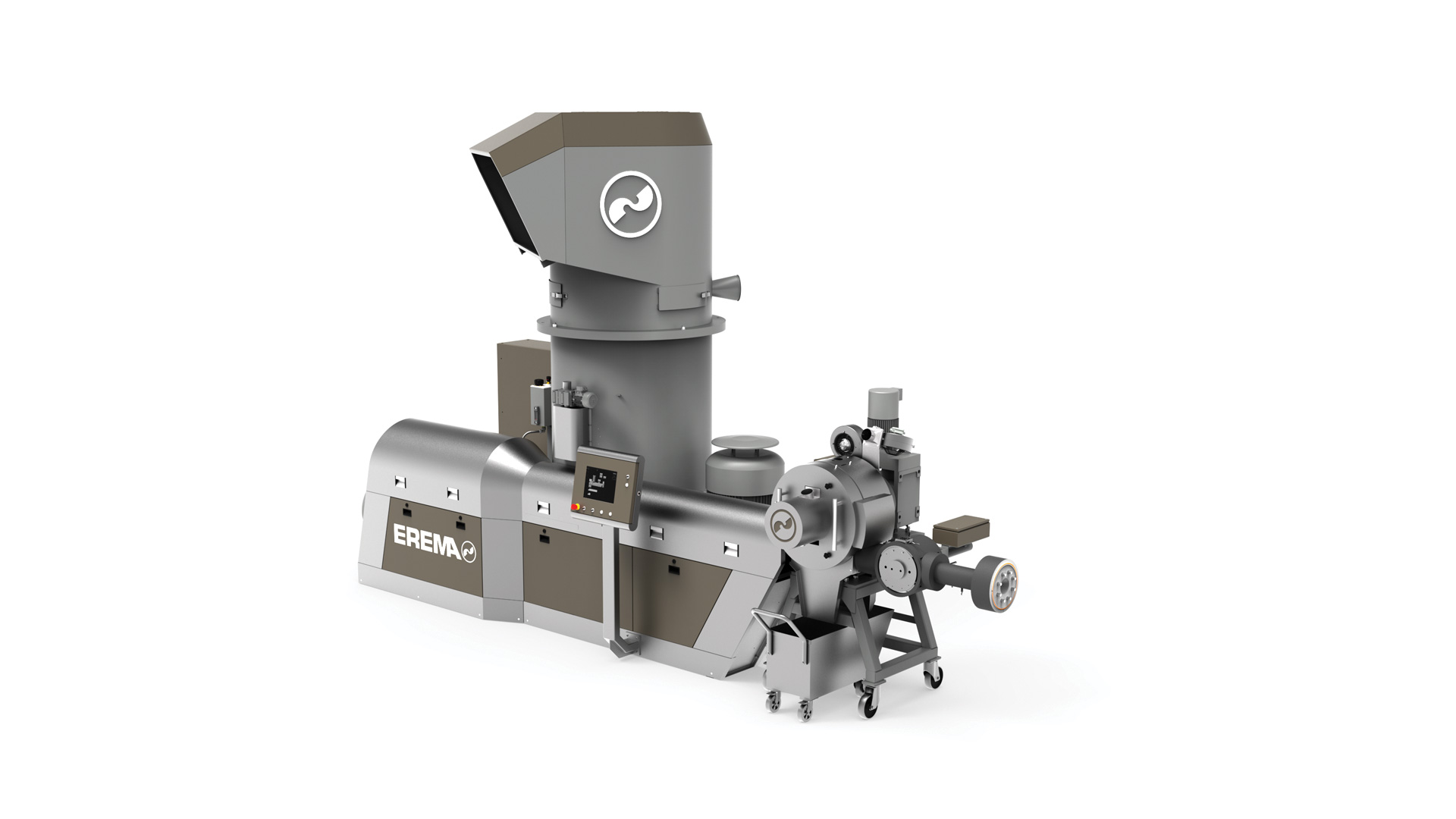

CHEMAREMA®

ideal mechanical preparation for optimal chemical recycling

The various extrusion systems in the CHEMAREMA® series provide the ideal mechanical material preparation at the start of the chemical recycling process. Material feed is reliable, continuous and energy-efficient - even at high throughputs.

The right CHEMAREMA® system for each specific application

Input material streams in chemical recycling vary widely in terms of polymer type, material shape and level of contamination. Moist and contaminated materials with a low bulk density (e.g.: packaging films) place particularly high demands on the system that feeds the material into the chemical recycling process. Thanks to its broad technology portfolio, the CHEMAREMA® series offers custom-built solutions to this challenge. This means that the extrusion systems are precisely designed to meet the requirements of each input stream - incorporating a high degree of flexibility to allow for any variances that occur in the material being fed into the system. Systems range from single-screw melt extruders with preconditioning unit (PCU), shredder-extruder combinations and vacuum-assisted extrusion solutions, through to cascade solutions with single- or twin-screw extrusion.

Several process steps combined in one plant

Thanks to the high degree of technology integration, the systems in the CHEMAREMA® series combine several essential process steps compactly in one plant, which would otherwise have to be solved with additional, upstream components. This saves costs both in investment and during operation and increases production efficiency. For example, the systems with PCU include the process steps of pre-drying, compacting and agglomerating the material for extrusion.

Video CHEMAREMA®

Highly efficient processing of post-consumer waste for chemical recycling at Electraplan, Hungary

Chemical and Mechanical Recycling - Colleagues or Competitors?

Download the Kunststoffe magazine, edition 01/2022

© Carl Hanser Verlag, München, Kunststoffe 1/2022