Business with bin liners, construction and agricultural films in the highly competitive environment is only effective and worthwhile if recycling materials are used for their production – up to 100% in some cases. The use of recyclate, however, is also recommended for other, primarily multilayer films for all applications from hygiene to packaging, not only for reasons of economy. The in-house recycling of film edge trim has long been a standard while a reverse integration from film to recycled pellet manufacturer has not. This can, however, make sense, as Reinhard Händel, Project Manager at Polifilm Extrusion GmbH in Weissandt-Gölzau is aware.

As one of the biggest producers of polyethylene film in Europe with a production capacity of 220,000 t/year which is achieved with more than 70 extrusion plants, recycling is extremely important at Polifilm. Reinhard Händel: “If you work properly with recycling materials instead of virgin you can save around 30% for every tonne of material processed and that corresponds to roughly 300 to 500 euros.” But recycling is also a statement. More and more consumers demand products which are more sustainable than what they are used to and we all know the extent of legal requirements. This is why Polifilm operates six central recycling lines in total – besides edge trim refeeding on every plant – working in four shifts and producing 25,000 tonnes of recycled pellets every year. “Our recycling facilities work 24/7, just like the film plants,” explains Reinhard Händel. The film and recycling plants have something else in common: they all have to cope with regular changes as the film producer‘s product portfolio is extremely wideranging.

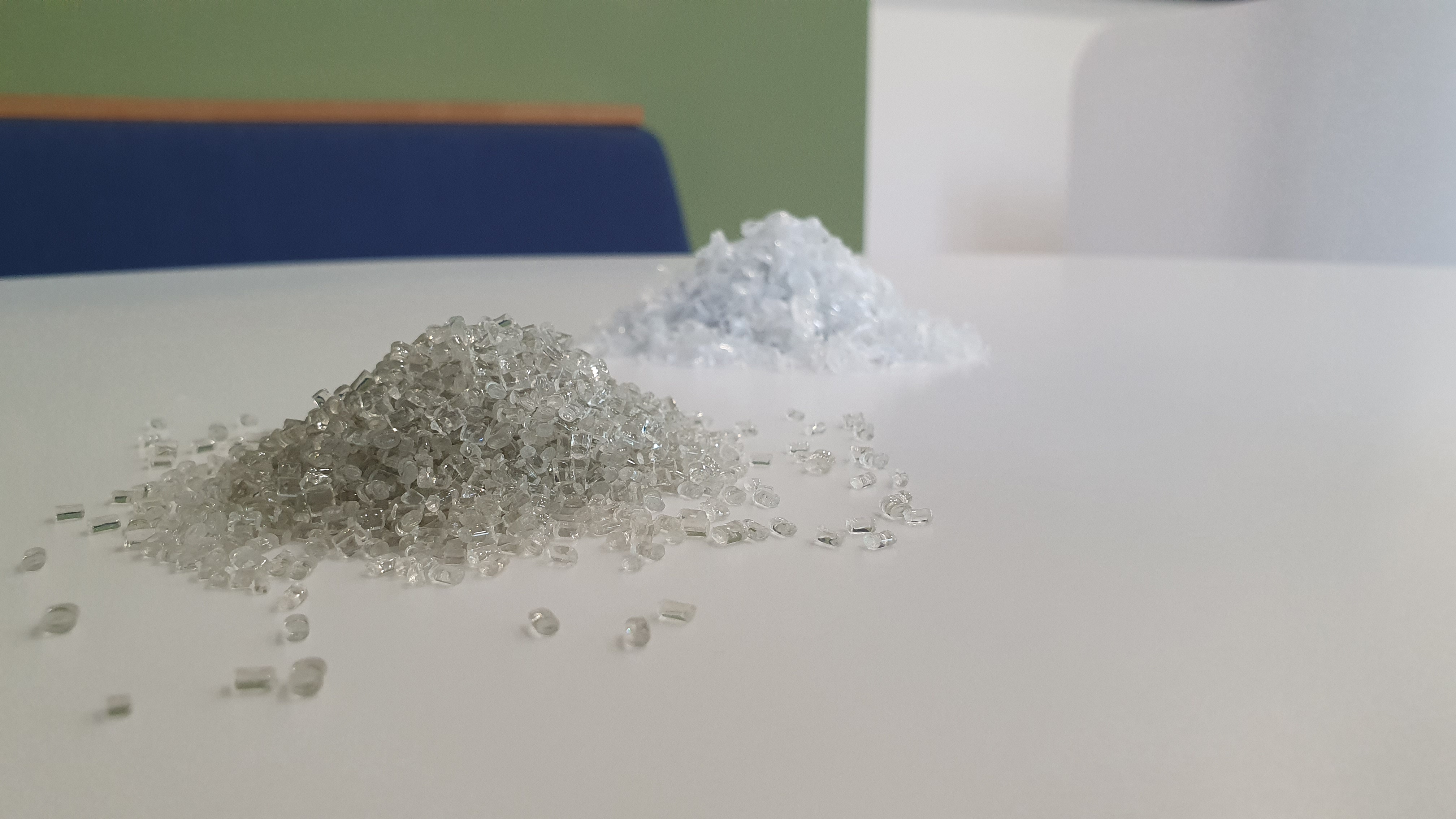

Besides technical films, packaging films, construction and agricultural films and stretch films which are produced in cast or blown film extrusion processes, Polifilm alone produces 80 different types of recycled pellets. Precise planning is crucial here.

Cutter/compactor guarantees constant material flow

Polifilm decided in favour of EREMA for its central recycling systems, “because they work without stuffing units and guarantee a very stable process,” as Reinhard Händel explains. The systems are also ideal for even very thin films. EREMA has made sure of this thanks to continuous optimisations in recent years. And this is one reason why Polifilm will soon be putting a sixth EREMA system into operation. The systems installed here are “T” systems for non-printed and “TVE plus” systems for printed film scrap. Unlike stuffing units, which are often used in the recycling plants of other manufacturers, the cutter/compactor has specific benefits: above all, the perfect preconditioning of the remaining material prior to extrusion is crucial for the quality of the recyclate. EREMA fulfils this requirement with its systems by combining a preconditioning unit with the recycling extruder. This means that films of varying thicknesses can be cut, heated and compacted to a uniform bulk density of around 350 kg/m³. The material which is compacted this way can be added continuously and pulsation and process fluctuations are ruled out. Another positive aspect of the cutter/compactor is the preheating of the materials so that less energy intake for plastification inside the extruder is required and thermomechanical stress on the polymer is minimised. Finally, the cutter/compactor carries out the degassing process. This is because moisture deposits on the film scrap can occur from time to time due to fluctuations in temperature and air humidity when in-house waste is kept in storage.

Author: Dipl.-Ing. (FH) Karin Regel, Editor K-PROFI

| Application: | Inhouse & industrial recycling |

|---|---|

| Materials: | Lightly printed films Non-printed films PE blown film |

| Product category: | INTAREMA |

EREMA and DORNIER combine machine components to create an innovative recycling solution

When two mechanical engineering technology leaders work together in order to fulfil specific customer requirements, unique recycling solutions are the result.